Sustainable Manufacturing in the Automotive Sector

The automotive industry is undergoing a transformative shift towards more sustainable practices in its manufacturing processes. This evolution is driven by increasing environmental regulations, consumer demand for eco-friendly products, and a growing understanding of the long-term benefits of resource efficiency. From material sourcing to production lines and end-of-life vehicle management, sustainability is becoming a core principle, influencing every stage of vehicle creation. This commitment aims to reduce the ecological footprint of vehicle production while fostering innovation and long-term viability for the sector.

How Electric Vehicles Influence Sustainable Manufacturing?

The rise of electric vehicles (EVs) is a significant driver for sustainable manufacturing within the automotive sector. The production of electric vehicles inherently encourages a re-evaluation of material choices, energy consumption during assembly, and overall supply chain management. Manufacturers are focusing on reducing the carbon footprint of battery production, exploring cleaner energy sources for factories, and optimizing logistics to minimize emissions. The push for electric mobility also stimulates innovation in lightweight materials and aerodynamic designs, further contributing to the efficiency of the final product and its environmental impact.

What Role Does Recycling Play in Automotive Sustainability?

Recycling is a critical component of achieving sustainability in the automotive industry. It encompasses not only the recovery of materials from end-of-life vehicles but also the integration of recycled content into new car parts. This approach reduces the demand for virgin resources, conserves energy, and minimizes waste sent to landfills. Manufacturers are actively developing closed-loop recycling systems for key materials like steel, aluminum, plastics, and especially battery components. The goal is to maximize material utility, ensuring that valuable resources remain in circulation for as long as possible, contributing to a circular economy model.

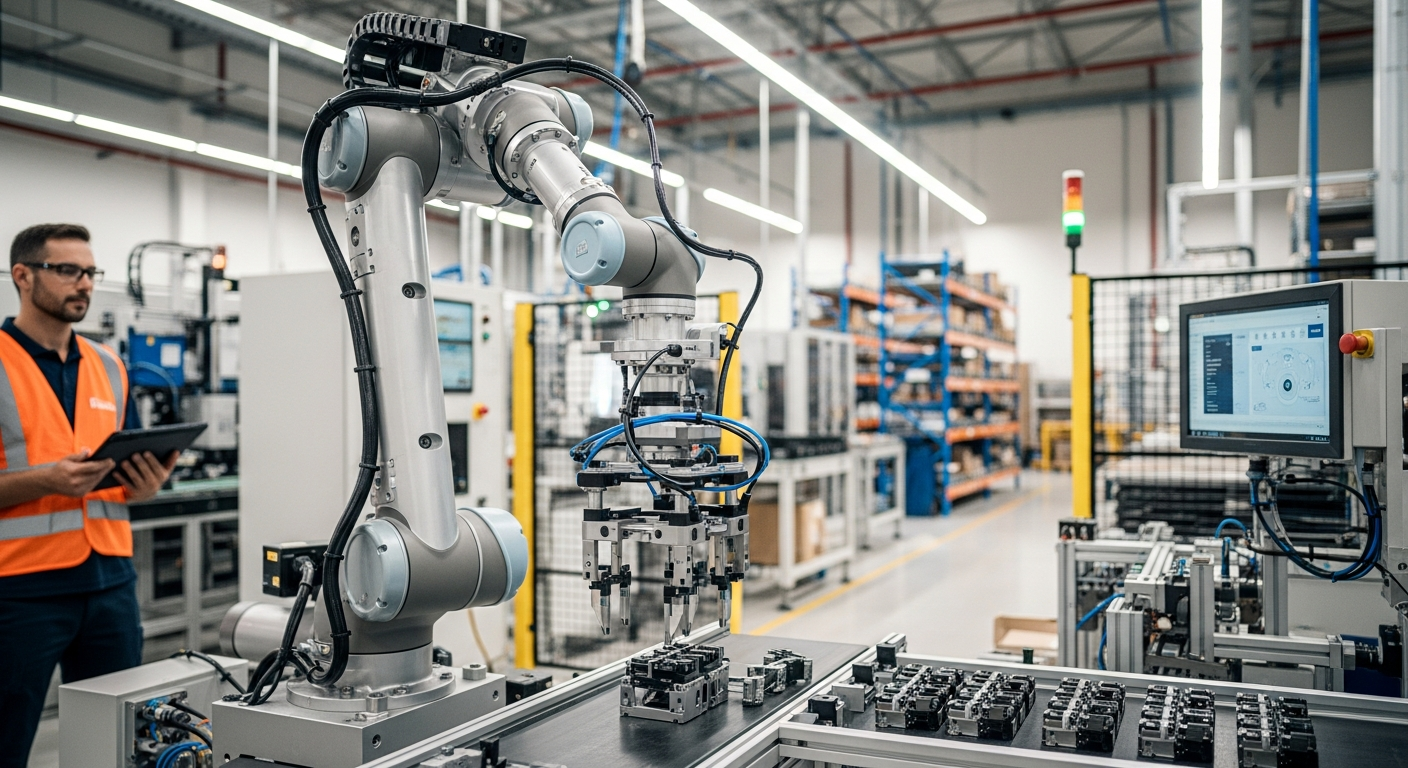

Enhancing Efficiency and Innovation in Production Processes

Efficiency and innovation are central to sustainable manufacturing. Automakers are investing in advanced technologies and methodologies to streamline production, reduce waste, and lower energy consumption. This includes the adoption of lean manufacturing principles, automation, and smart factory solutions that monitor resource use in real-time. Innovations in processes such as additive manufacturing (3D printing) can also lead to more efficient material use and reduced scrap. By continuously seeking more efficient and innovative ways to produce vehicles, the industry can significantly cut down on its environmental footprint while maintaining high-quality output.

Sustainable Design and Engineering Principles

Integrating sustainability from the initial design and engineering phases is crucial for the automotive sector. This involves considering the entire lifecycle of a vehicle, from material extraction to manufacturing, use, and eventual disposal or recycling. Designers and engineers are tasked with selecting materials that are durable, lightweight, and recyclable, while also minimizing the number of different materials used to simplify recycling processes. The focus is on creating vehicles that are not only fuel-efficient or electric but also environmentally responsible in their construction, promoting longevity and ease of material recovery at the end of their service life.

Advancements in Battery Technology for Environmental Impact

Battery technology is at the forefront of the electric vehicle revolution and plays a pivotal role in the environmental impact of sustainable manufacturing. Significant advancements are being made to improve battery efficiency, reduce reliance on critical raw materials, and enhance their recyclability. Research and development are focused on creating batteries with longer lifespans, faster charging capabilities, and lower environmental footprints during production. Furthermore, efforts are underway to establish robust second-life applications for EV batteries, such as energy storage for homes or grids, before they are eventually recycled, maximizing their utility and minimizing waste.

| Company Name | Sustainable Practices | Key Features/Benefits |

|---|---|---|

| Volvo Cars | Climate-neutral manufacturing, circular economy focus | Aiming for circular business model, reducing material impact |

| BMW Group | Resource efficiency, green energy sourcing | High percentage of recycled materials in vehicles, renewable energy in production |

| Volkswagen Group | Decarbonization program, e-mobility investment | Targets carbon-neutral production, expanding EV portfolio |

| Toyota | Environmental Challenge 2050, water conservation | Zero CO2 emissions from new vehicles and plants, water usage reduction |

| Ford Motor Company | Renewable energy commitments, sustainable materials | Investing in solar and wind power, using plant-based and recycled materials |

The Path Forward for Automotive Sustainability

Sustainable manufacturing in the automotive sector represents a holistic approach to vehicle production that considers environmental, social, and economic factors. It is a continuous journey involving ongoing research, development, and collaboration across the industry. As technology evolves and consumer expectations shift, the commitment to sustainability will only deepen, leading to more efficient processes, innovative materials, and ultimately, a greener future for transportation worldwide. The integration of electric powertrains, advanced recycling techniques, and eco-conscious design principles are all converging to redefine what it means to build a vehicle responsibly.