Advanced Robotics in Industrial Automation

Advanced robotics is fundamentally reshaping the landscape of industrial automation, introducing unprecedented levels of precision, speed, and efficiency across various sectors. These sophisticated machines are moving beyond simple repetitive tasks, now incorporating artificial intelligence, machine learning, and advanced sensor technologies to perform complex operations, adapt to changing environments, and collaborate with human workers. This evolution marks a significant shift in how industries approach manufacturing, logistics, and overall operational management, promising a future where production processes are more agile, data-driven, and resilient.

Robotics in Modern Manufacturing and Production

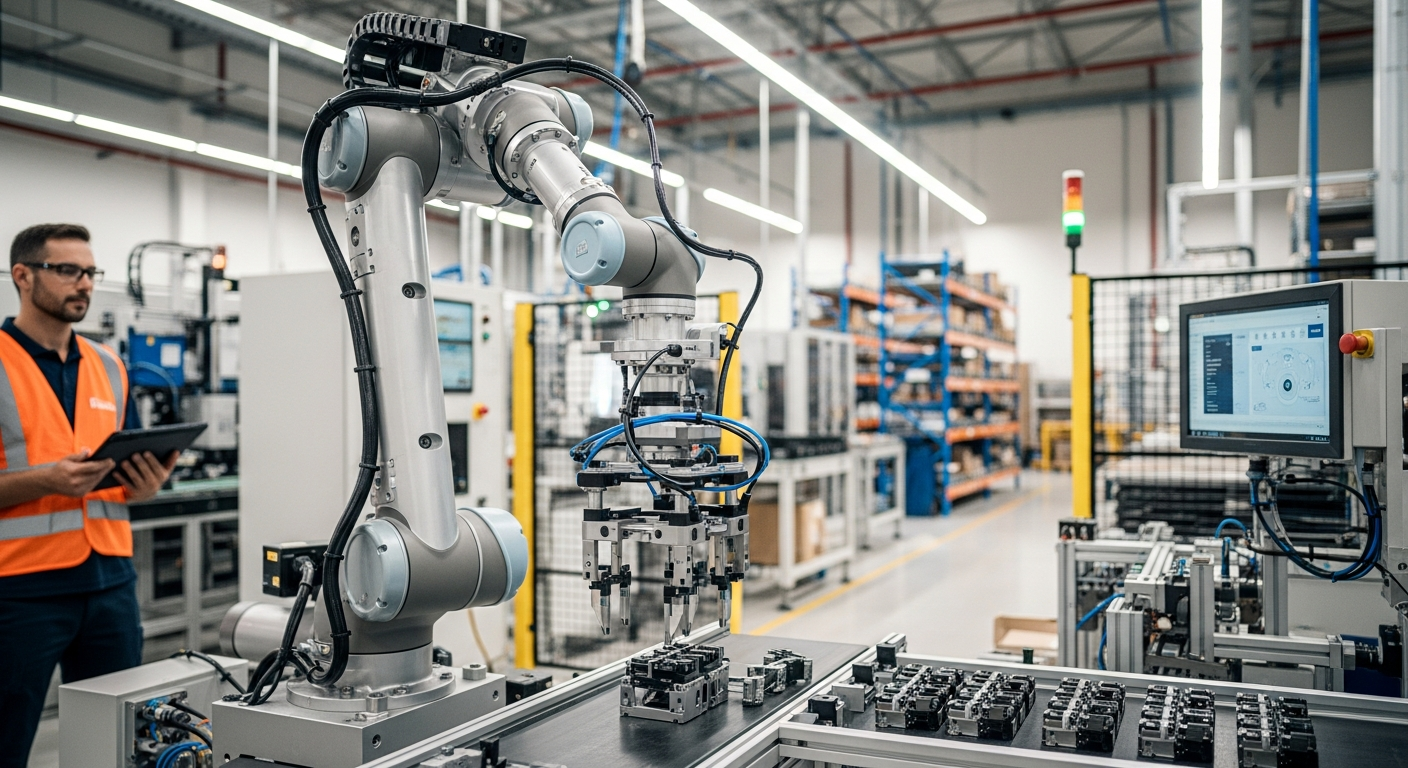

Modern manufacturing and production environments are increasingly leveraging advanced robotics to enhance various aspects of their operations. These robots are instrumental in tasks requiring high precision and repetitive actions, such as assembly, welding, painting, and material handling. Their ability to maintain consistent quality and speed significantly improves production throughput and reduces human error. Furthermore, advanced vision systems allow robots to inspect products for defects, ensuring higher quality control standards are met before items proceed to the next stage of the production line. This integration not only boosts efficiency but also contributes to a safer working environment by taking over hazardous or physically demanding jobs.

Enhancing Supply Chain and Logistics Operations

The impact of advanced robotics extends significantly into supply chain and logistics, transforming how goods are moved, stored, and managed. Autonomous Mobile Robots (AMRs) and Automated Guided Vehicles (AGVs) are becoming common sights in warehouses and distribution centers, efficiently transporting materials and finished products. These systems optimize routes, reduce labor costs, and accelerate order fulfillment, crucial elements for competitive commerce. Automated Storage and Retrieval Systems (AS/RS) further enhance space utilization and inventory management, ensuring that the right products are available at the right time. The integration of robotics in logistics operations creates a more streamlined, responsive, and resilient supply chain.

Driving Enterprise Efficiency and Innovation

For enterprises across various industries, the adoption of advanced robotics is a key driver for overall efficiency and innovation. By automating routine and complex tasks, companies can reallocate human talent to more strategic and creative roles, fostering a culture of continuous improvement and new product development. Robotics enable manufacturers to achieve higher output with fewer resources, optimize energy consumption, and reduce waste, contributing to a more lean and sustainable operational model. This pursuit of efficiency often leads to significant cost savings and improved competitiveness in global markets, positioning businesses for sustained growth.

Strategic Automation for Growth and Performance

Implementing advanced automation through robotics is a strategic decision that can significantly impact a company’s growth and performance. Businesses are increasingly developing comprehensive automation strategies to identify areas where robotics can provide the most value, from enhancing production capabilities to improving customer service through faster delivery. The data collected by these automated systems also offers valuable insights into operational performance, allowing for continuous optimization and informed decision-making. Effective management of these robotic systems, coupled with ongoing training for human staff, ensures that the investment in automation translates into measurable improvements in productivity, quality, and market responsiveness.

Digitalization, Sustainability, and Resilience in Modern Industry

Advanced robotics plays a pivotal role in the ongoing digitalization of industry, serving as a cornerstone of Industry 4.0 initiatives. These intelligent machines are often connected within broader industrial internet of things (IIoT) ecosystems, enabling real-time data exchange and predictive maintenance. Beyond digitalization, robotics contribute to sustainability by optimizing resource usage, minimizing material waste, and potentially reducing the carbon footprint of production processes. Furthermore, by automating critical operations, businesses can build greater resilience against disruptions, such as labor shortages or unforeseen global events, ensuring continuous production and stable operations even in challenging circumstances. This holistic approach strengthens the industry’s capacity for long-term endurance.

Considerations for Robotics Implementation

Integrating advanced robotics into industrial settings involves careful planning and consideration of various factors. This includes evaluating the specific needs of an operation, assessing the compatibility of robotic systems with existing infrastructure, and understanding the potential for scalability. The initial investment in robotic technology can vary widely depending on the complexity of the robots, their capabilities, and the scope of the automation project. Factors such as customization, integration services, and ongoing maintenance also contribute to the overall cost. Many providers offer modular solutions that can be scaled over time, allowing businesses to adapt their automation levels as needs evolve and budgets permit. It is important to engage with providers who offer comprehensive support, from initial consultation and installation to training and long-term service agreements, to ensure a successful deployment and maximize the return on investment.

Prices, rates, or cost estimates mentioned in this article are based on the latest available information but may change over time. Independent research is advised before making financial decisions.

Advanced robotics is transforming industrial automation, offering profound benefits across manufacturing, supply chain, and enterprise operations. From boosting production efficiency and ensuring quality control to enabling greater supply chain resilience and driving strategic growth, these technologies are redefining industry standards. As businesses continue to embrace digitalization and innovation, the role of intelligent automation will only expand, shaping a more productive, sustainable, and adaptive industrial future for the global economy.