Lightweight Composites for Enhanced Vehicle Dynamics

The automotive industry is continually seeking innovative solutions to improve vehicle performance, efficiency, and sustainability. A key area of focus involves the integration of lightweight composite materials into vehicle design and manufacturing. These advanced materials offer a compelling pathway to reduce overall vehicle weight, which in turn profoundly impacts a car's dynamics, fuel economy, and environmental footprint, paving the way for the next generation of transport solutions.

The Role of Lightweight Materials in Modern Vehicle Design

Lightweight materials are transforming the automotive landscape by offering a superior strength-to-weight ratio compared to traditional metals like steel and aluminum. Composites, such as carbon fiber reinforced polymers (CFRPs) and glass fiber reinforced polymers (GFRPs), consist of a matrix material reinforced with fibers, creating a material that is both strong and exceptionally light. This fundamental shift in material science enables engineers to rethink vehicle architecture, moving beyond conventional limitations to create more efficient and dynamic vehicles.

The adoption of these materials is driven by stringent regulations on emissions and the growing consumer demand for vehicles that offer better performance, safety, and fuel efficiency. By reducing the mass of individual components and the overall vehicle structure, composites contribute significantly to achieving these goals, representing a major innovation in vehicle design and construction.

Enhancing Vehicle Performance and Fuel Efficiency

Reducing vehicle weight directly translates into improved performance across various metrics. Lighter vehicles require less energy to accelerate, brake, and navigate turns, leading to enhanced driving dynamics and a more responsive feel. This is particularly noticeable in acceleration times and handling characteristics, where a lower mass allows for quicker reactions and better agility on the road.

Beyond performance, the most significant benefit of lightweighting is the improvement in fuel efficiency. For internal combustion engine vehicles, a lighter body means less fuel consumption and lower CO2 emissions. For electric vehicles, weight reduction extends battery range, addressing a key concern for many drivers and supporting the broader shift towards sustainable transport. This efficiency gain is a cornerstone of modern automotive technology.

Composites in Electric and Autonomous Vehicle Systems

The advent of electric and autonomous vehicles presents unique challenges and opportunities for lightweight composites. For electric vehicles, the heavy battery packs necessitate significant weight savings elsewhere in the vehicle to maintain a competitive range and performance. Composites are ideal for battery enclosures, structural components, and body panels, helping to offset the battery’s mass and optimize the vehicle’s overall energy consumption.

In autonomous vehicles, composites can be integrated into the structural framework to provide robust yet light mounting points for sensors, cameras, and lidar systems, which are critical for safe and reliable operation. Their ability to be molded into complex shapes also aids in aerodynamic design, further improving efficiency and integrating advanced digital systems seamlessly into the vehicle’s form factor.

Advancements in Manufacturing and Sustainable Mobility

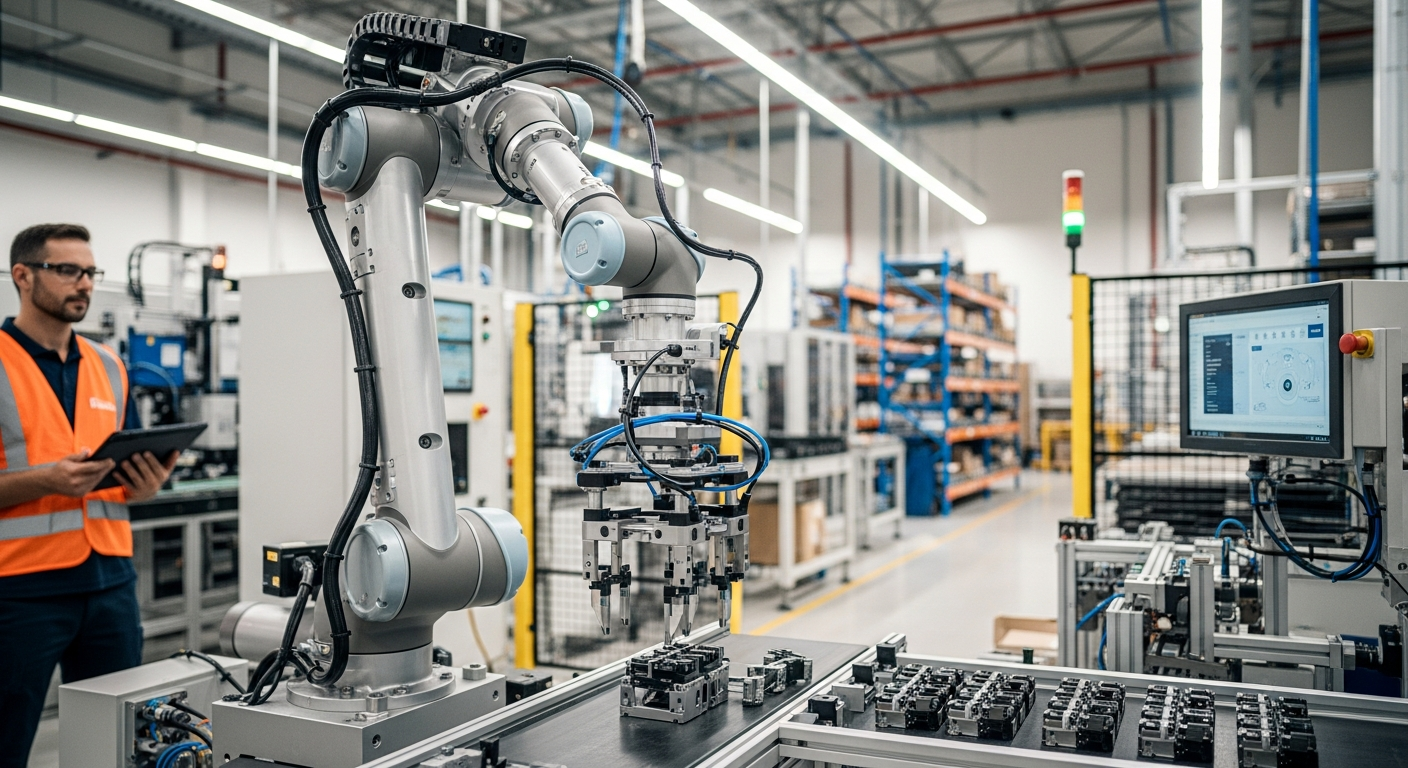

The manufacturing processes for lightweight composites have seen considerable advancements, enabling higher production volumes and more cost-effective integration into automotive assembly lines. Techniques like automated fiber placement, resin transfer molding, and thermoplastic composites are making the production of complex parts faster and more efficient. These innovations are crucial for scaling up composite use across different vehicle segments.

Furthermore, the focus on sustainable mobility extends to the lifecycle of materials. Research and development are actively exploring improved recycling methods for composite materials to reduce waste and minimize their environmental impact. This drive towards a circular economy for composites is vital for their long-term viability and contribution to a truly sustainable future for transport.

Impact on Vehicle Safety and Structural Integrity

Despite their light weight, advanced composites are engineered to provide exceptional crashworthiness and structural integrity. Their unique ability to absorb impact energy through controlled deformation and fracture mechanisms makes them highly effective in protecting occupants during a collision. Unlike metals that may deform plastically, composites can be designed to crush in specific ways, distributing forces and maintaining the passenger cell’s integrity.

This inherent strength and stiffness contribute to a safer vehicle structure, offering enhanced protection for drivers and passengers. The integration of these materials into critical chassis and body components ensures that safety standards are met or exceeded, even as vehicles become lighter and more efficient, showcasing a balance between performance and protection.

Cost Considerations and the Future of Composite Integration

The initial cost of lightweight composite materials and their associated manufacturing processes can be higher compared to traditional steel or aluminum. This often stems from the raw material expense, specialized tooling requirements, and the complexity of production techniques. However, the long-term benefits, including improved fuel economy, extended electric vehicle range, and enhanced performance, can offset these upfront investments over the vehicle’s lifespan.

As manufacturing technologies mature and economies of scale are achieved, the cost of composites is expected to become more competitive, facilitating broader adoption across the automotive industry. Continued research into novel composite formulations and more efficient production methods is essential for driving down costs and making these advanced materials accessible to a wider range of vehicles, impacting the future of road infrastructure and mobility systems.

Prices, rates, or cost estimates mentioned in this article are based on the latest available information but may change over time. Independent research is advised before making financial decisions.

The integration of lightweight composites represents a significant evolution in automotive engineering, offering tangible benefits in performance, efficiency, and safety. As the industry continues to innovate, these materials will play an increasingly critical role in shaping the design and capabilities of future vehicles, contributing to more sustainable and dynamic transport solutions globally. The ongoing development in material science and manufacturing processes promises to unlock even greater potential, driving the next generation of mobility forward.