Emerging Technologies Reshaping Production

The landscape of global production is undergoing a significant transformation, driven by a wave of emerging technologies. From advanced automation to sophisticated data analytics, these innovations are fundamentally altering how goods are manufactured, distributed, and managed across various industries. Businesses worldwide are exploring and adopting these tools to enhance various aspects of their operations, from the factory floor to the broader supply chain network, aiming for greater efficiency, resilience, and adaptability in an ever-evolving market.

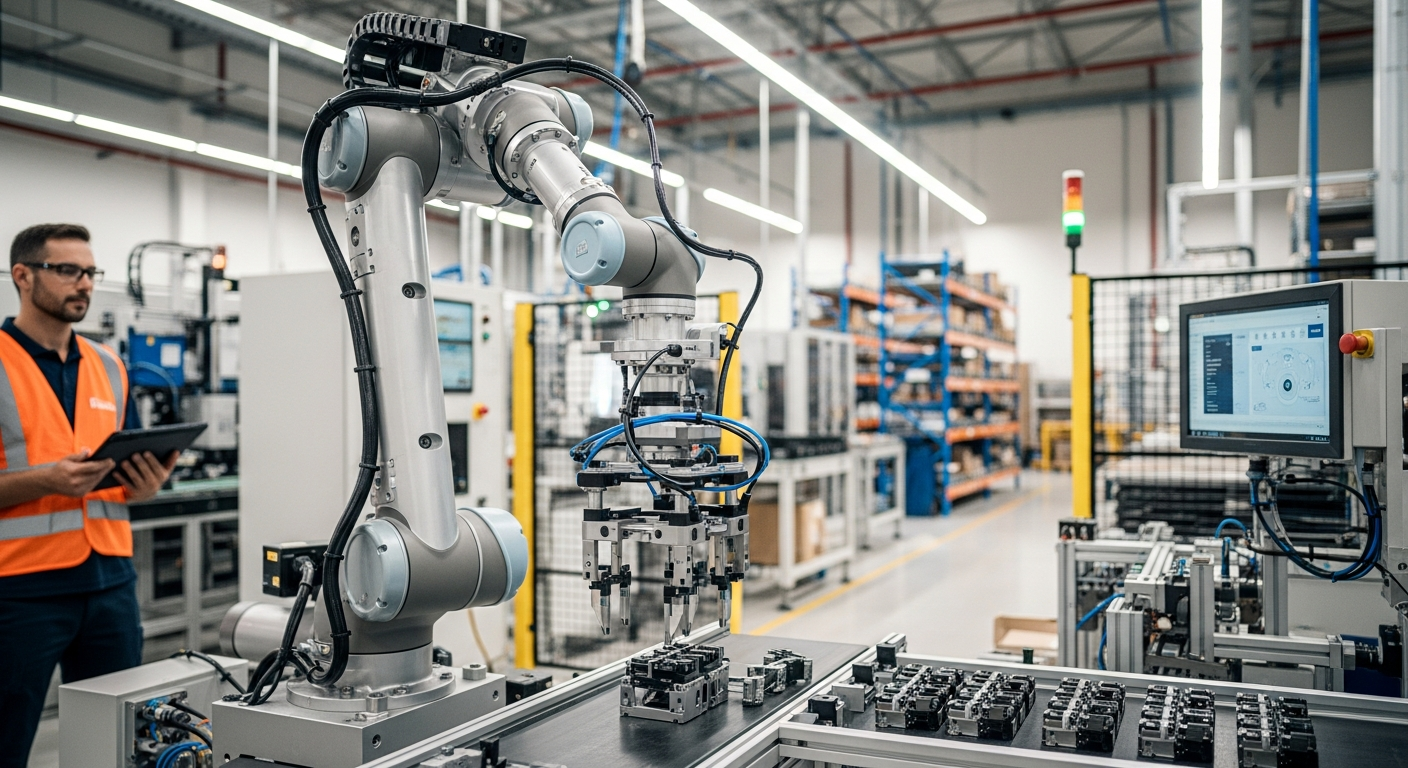

Advancements in Manufacturing and Production

The core of industrial activity, manufacturing, is experiencing a profound shift due to technological innovation. Modern production facilities are increasingly integrating smart machinery, often referred to as Industry 4.0 technologies. This includes the use of industrial Internet of Things (IIoT) devices that connect machines and systems, enabling real-time data collection and analysis. Such integration allows for predictive maintenance, optimized resource allocation, and a higher degree of customization in production lines. The goal is to create more agile and responsive manufacturing environments that can quickly adapt to changing market demands and minimize downtime.

Streamlining Operations Through Automation

Automation plays a pivotal role in enhancing industrial operations, extending beyond traditional robotics. Advanced automation now encompasses artificial intelligence (AI) and machine learning (ML) algorithms that can manage complex processes, from quality control to scheduling. These intelligent systems can analyze vast datasets to identify patterns and make decisions that optimize workflow and reduce human error. This not only boosts efficiency but also frees up human workers for more complex problem-solving and creative tasks, fostering a more collaborative environment between humans and machines within the enterprise.

Transforming Supply Chain and Logistics

The efficiency of a business is heavily reliant on its supply chain and logistics. Emerging technologies are providing unprecedented visibility and control over these complex networks. Blockchain technology, for instance, offers a secure and transparent way to track products from origin to destination, improving accountability and reducing fraud. AI-powered analytics can predict demand fluctuations, optimize routing for logistics, and manage inventory more effectively, leading to reduced waste and faster delivery times. These advancements contribute to building more resilient and responsive supply chains capable of navigating global disruptions.

Driving Efficiency and Sustainability in Industrial Settings

Beyond just speed and cost reduction, modern industrial technology is increasingly focused on sustainability. Advanced sensors and data analytics allow businesses to monitor energy consumption and waste generation with precision, identifying areas for improvement. Technologies like additive manufacturing (3D printing) can reduce material waste by building objects layer by layer, only using what is necessary. Furthermore, optimized production processes, driven by automation and AI, can lead to more efficient use of raw materials and energy, contributing to a smaller environmental footprint and promoting long-term sustainability goals within industrial operations.

The Role of Innovation in Enterprise Management

For enterprise management, embracing these innovations is crucial for maintaining a competitive edge. Decision-makers are leveraging data-driven insights from connected systems to make more informed strategic choices, from product development to market entry. The integration of various technological platforms requires a holistic approach to management, ensuring that different departments can communicate and collaborate effectively. Continuous innovation in technology adoption and process refinement becomes a cornerstone of modern industrial strategy, enabling businesses to adapt and thrive in dynamic global markets.

Costs and Considerations for Technology Implementation

Implementing new technologies within business and industrial settings involves varying levels of investment, which can depend on the scale of adoption, the specific technologies chosen, and the existing infrastructure. For instance, initial investments in IIoT sensors, AI software licenses, or advanced robotics can range from moderate to substantial. Operational costs may include maintenance, software subscriptions, and specialized training for personnel. Businesses often start with pilot programs to assess the return on investment before a full-scale rollout, considering both upfront capital expenditure and long-term operational savings and efficiency gains.

| Product/Service | Provider | Cost Estimation |

|---|---|---|

| Predictive Maintenance Software | Siemens MindSphere | Variable, subscription-based |

| Industrial IoT Platform | PTC ThingWorx | Variable, license-based |

| Robotic Process Automation (RPA) | UiPath | Variable, based on bot usage/licenses |

| Supply Chain Visibility Solutions | Blue Yonder | Variable, enterprise-level pricing |

| Additive Manufacturing (Industrial 3D Printers) | EOS GmbH | High initial investment, variable material costs |

Prices, rates, or cost estimates mentioned in this article are based on the latest available information but may change over time. Independent research is advised before making financial decisions.

The ongoing evolution of technology continues to reshape the industrial and business landscape, presenting both challenges and opportunities. By strategically adopting and integrating these emerging tools, organizations can enhance their manufacturing capabilities, optimize operational efficiency, strengthen supply chain resilience, and advance their sustainability efforts. The focus remains on leveraging these innovations to foster growth, adaptability, and a more competitive position in the global economy, ensuring that businesses are well-equipped for the future of production.