Adaptive Manufacturing: Reshaping Production Paradigms

In today's rapidly evolving industrial landscape, adaptive manufacturing emerges as a game-changing approach, revolutionizing how businesses respond to market demands and operational challenges. This innovative methodology combines flexible production systems, real-time data analytics, and advanced robotics to create agile manufacturing environments capable of swift reconfiguration and optimization. As companies grapple with unpredictable market shifts and customer expectations, adaptive manufacturing offers a promising solution to enhance competitiveness and operational resilience.

The Foundation of Adaptive Manufacturing

At its core, adaptive manufacturing is built on a foundation of flexibility and responsiveness. Traditional manufacturing models often struggle with rigid production lines and lengthy setup times, making it challenging to adapt to sudden changes in demand or product specifications. Adaptive manufacturing addresses these limitations by incorporating modular production units, advanced automation systems, and intelligent software platforms that enable rapid reconfiguration of manufacturing processes.

One key component of adaptive manufacturing is the use of flexible manufacturing systems (FMS). These systems consist of highly automated workstations connected by material handling systems, all controlled by a central computer. FMS allows for the production of a variety of products with minimal manual intervention, significantly reducing setup times and increasing overall productivity.

Real-Time Data Analytics: The Driving Force

The power of adaptive manufacturing lies in its ability to leverage real-time data analytics to inform decision-making and optimize production processes. By integrating sensors and Internet of Things (IoT) devices throughout the production line, manufacturers can collect vast amounts of data on machine performance, product quality, and overall operational efficiency.

Advanced analytics platforms process this data in real-time, providing valuable insights that enable manufacturers to identify bottlenecks, predict maintenance needs, and optimize resource allocation. This constant stream of actionable information allows for dynamic adjustments to production schedules, ensuring that manufacturing operations remain aligned with current market demands and operational constraints.

The Role of Advanced Robotics in Adaptive Manufacturing

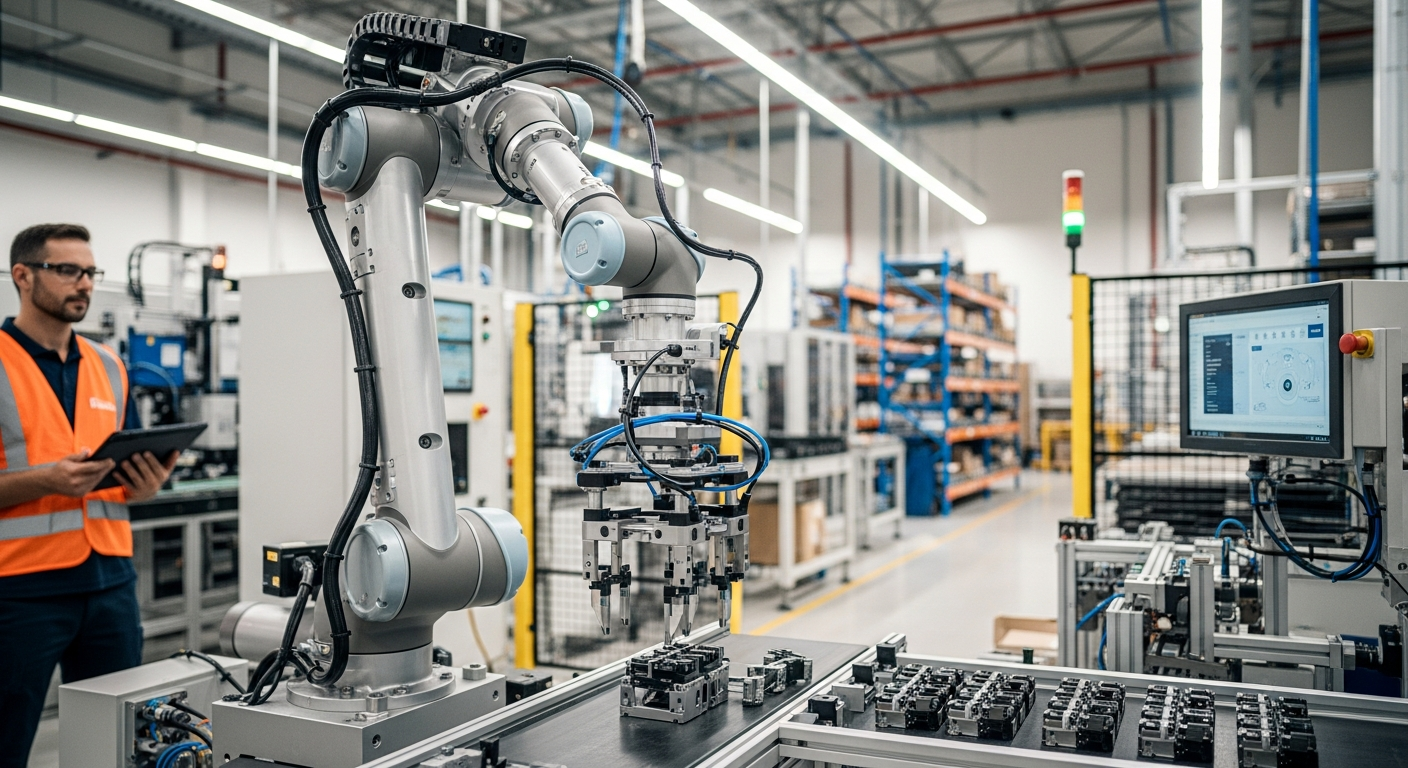

Advanced robotics plays a crucial role in the implementation of adaptive manufacturing strategies. Unlike traditional industrial robots programmed for specific, repetitive tasks, modern robotic systems in adaptive manufacturing environments are designed for versatility and easy reprogramming.

Collaborative robots, or cobots, represent a significant advancement in this area. These robots are designed to work alongside human operators, combining the precision and strength of machines with the problem-solving skills and adaptability of humans. Cobots can be quickly reprogrammed to handle different tasks, making them ideal for adaptive manufacturing environments where production requirements may change frequently.

Customization at Scale: Meeting Individual Consumer Demands

One of the most significant advantages of adaptive manufacturing is its ability to facilitate mass customization. Traditional manufacturing models often struggle to balance the efficiency of mass production with the growing demand for personalized products. Adaptive manufacturing bridges this gap by enabling manufacturers to produce customized goods at scale without sacrificing efficiency or cost-effectiveness.

By leveraging flexible production systems and advanced digital technologies, companies can offer customers a higher degree of product customization while maintaining competitive pricing. This capability is particularly valuable in industries such as automotive, consumer electronics, and fashion, where personalization is increasingly becoming a key differentiator in the market.

Challenges and Considerations in Implementing Adaptive Manufacturing

While the benefits of adaptive manufacturing are clear, implementing this approach comes with its own set of challenges. One of the primary hurdles is the significant upfront investment required in technology and infrastructure. Companies must carefully evaluate the potential return on investment and develop a clear implementation strategy to ensure successful adoption.

Another critical consideration is the need for a skilled workforce capable of operating and maintaining advanced manufacturing systems. As adaptive manufacturing relies heavily on complex technologies and data-driven decision-making, companies must invest in comprehensive training programs and may need to recruit new talent with specialized skills in areas such as robotics, data analytics, and systems integration.

Key Strategies for Successful Adaptive Manufacturing Implementation

• Conduct a thorough assessment of current manufacturing processes to identify areas for improvement and potential bottlenecks

• Invest in modular and flexible production equipment that can be easily reconfigured for different product lines

• Implement robust data collection and analytics systems to enable real-time decision-making and process optimization

• Develop a comprehensive training program to upskill existing employees and attract new talent with relevant expertise

• Start with small-scale pilot projects to test and refine adaptive manufacturing concepts before full-scale implementation

• Foster a culture of continuous improvement and innovation to support ongoing adaptation to market changes and technological advancements

As the industrial landscape continues to evolve, adaptive manufacturing stands out as a powerful approach for companies seeking to enhance their competitiveness and resilience. By embracing flexibility, leveraging real-time data analytics, and integrating advanced robotics, businesses can create agile production environments capable of meeting the dynamic demands of today’s markets. While challenges exist, the potential benefits of adaptive manufacturing make it a compelling strategy for forward-thinking companies aiming to thrive in an increasingly unpredictable business environment.