Collaborative Manufacturing Networks: Redefining Production Paradigms

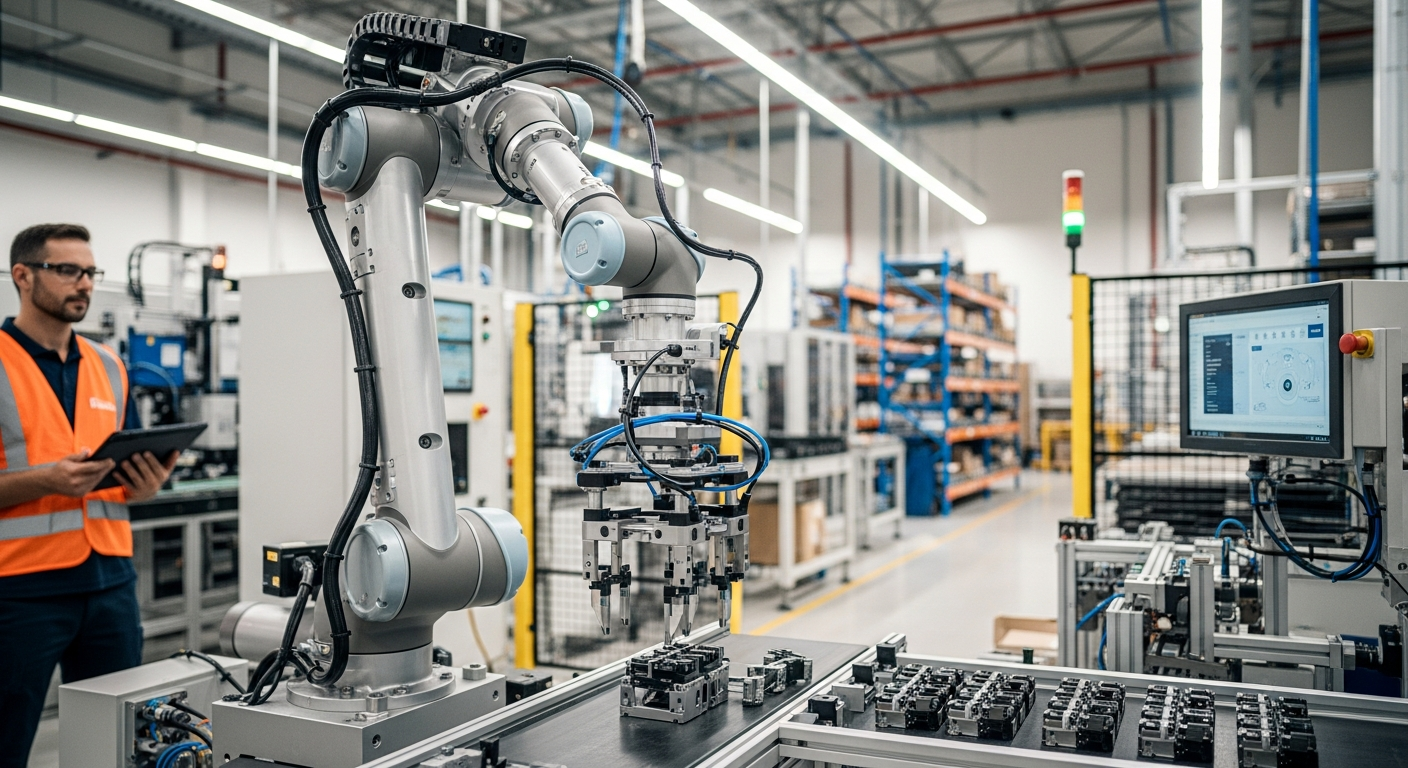

Collaborative manufacturing networks are reshaping traditional production models, fostering innovation, and boosting competitiveness in today's rapidly evolving industrial landscape. This emerging approach leverages shared resources, expertise, and technologies across multiple organizations, creating a synergistic ecosystem that drives efficiency, flexibility, and growth.

In the 1980s and 1990s, the rise of lean manufacturing and just-in-time production systems laid the groundwork for more flexible and responsive production models. Concurrently, advancements in information technology and the internet facilitated seamless communication and data sharing between organizations. These developments set the stage for the evolution of collaborative manufacturing networks.

The early 2000s saw pioneering companies experimenting with collaborative approaches, forming strategic partnerships and joint ventures to share resources and expertise. As these initiatives proved successful, the concept gained traction, leading to the development of more formalized collaborative manufacturing networks.

Core Principles of Collaborative Manufacturing Networks

Collaborative manufacturing networks are built on several fundamental principles that differentiate them from traditional production models:

-

Resource Sharing: Participants in the network share physical assets, technologies, and expertise, maximizing utilization and reducing individual capital investments.

-

Distributed Production: Manufacturing processes are distributed across multiple facilities, allowing for localized production and greater flexibility in meeting demand fluctuations.

-

Open Innovation: The network fosters a culture of open innovation, encouraging the exchange of ideas and technologies among participants to drive continuous improvement.

-

Dynamic Collaboration: Relationships within the network are fluid, with organizations forming temporary alliances based on specific project requirements or market opportunities.

-

Technology Integration: Advanced digital technologies, such as cloud computing, Internet of Things (IoT), and artificial intelligence, are leveraged to enable seamless coordination and real-time decision-making across the network.

Benefits and Challenges of Collaborative Manufacturing Networks

The adoption of collaborative manufacturing networks offers numerous advantages to participating organizations:

-

Enhanced Flexibility: The distributed nature of production allows for rapid scaling and adaptation to market changes.

-

Cost Reduction: Shared resources and economies of scale lead to reduced operational and capital costs for individual participants.

-

Accelerated Innovation: Cross-pollination of ideas and technologies within the network drives faster innovation cycles.

-

Risk Mitigation: Diversified production capabilities and shared investments help mitigate risks associated with market volatility and technological obsolescence.

-

Access to New Markets: Collaboration enables smaller manufacturers to access larger markets and compete with established players.

However, implementing collaborative manufacturing networks also presents several challenges:

-

Trust and Intellectual Property: Balancing open collaboration with the protection of proprietary information and technologies can be complex.

-

Standardization: Establishing common standards and protocols across diverse organizations is crucial for seamless integration.

-

Governance: Developing effective governance structures to manage the network and resolve conflicts is essential.

-

Cultural Shift: Transitioning from a competitive to a collaborative mindset requires significant cultural change within organizations.

-

Technology Investment: Implementing the necessary digital infrastructure for effective collaboration can be costly and time-consuming.

Case Study: The Collaborative Manufacturing Network in the Automotive Industry

The automotive industry provides a compelling example of collaborative manufacturing networks in action. In recent years, leading automakers have formed strategic alliances and joint ventures to share platforms, technologies, and production facilities.

For instance, the Renault-Nissan-Mitsubishi Alliance has successfully implemented a collaborative manufacturing approach. The alliance shares vehicle platforms, powertrains, and manufacturing facilities across its brands, resulting in significant cost savings and improved efficiency. This collaboration has enabled the alliance to become one of the world’s largest automotive groups, producing over 10 million vehicles annually.

The network extends beyond the core alliance, incorporating suppliers, technology partners, and even competitors in specific projects. This approach has accelerated the development of electric and autonomous vehicles, with the alliance leveraging shared resources to compete effectively in these emerging markets.

Future Trends in Collaborative Manufacturing Networks

As collaborative manufacturing networks continue to evolve, several trends are shaping their future:

-

Blockchain Integration: Blockchain technology is being explored to enhance trust, transparency, and traceability within collaborative networks.

-

AI-Driven Optimization: Advanced AI algorithms are being deployed to optimize resource allocation and production scheduling across the network.

-

Virtual Reality Collaboration: VR technologies are enabling remote collaboration in design and prototyping processes, further breaking down geographical barriers.

-

Circular Economy Integration: Collaborative networks are increasingly incorporating circular economy principles, focusing on sustainability and resource efficiency.

-

Cross-Industry Collaboration: Networks are expanding beyond traditional industry boundaries, fostering innovation through cross-sector collaboration.

Key Strategies for Implementing Collaborative Manufacturing Networks

• Conduct a thorough assessment of your organization’s strengths, weaknesses, and strategic goals before entering a collaborative network.

• Invest in robust digital infrastructure to enable seamless communication and data sharing across the network.

• Develop clear governance structures and intellectual property agreements to manage collaboration effectively.

• Foster a culture of trust and open communication within your organization and with network partners.

• Start with small-scale collaborations and gradually expand as trust and capabilities grow.

• Continuously evaluate and optimize network performance, adjusting partnerships and processes as needed.

• Invest in training and development programs to equip your workforce with the skills needed for effective collaboration.

In conclusion, collaborative manufacturing networks represent a paradigm shift in industrial production, offering unprecedented opportunities for efficiency, innovation, and growth. As organizations navigate the complexities of this new model, those that successfully harness the power of collaboration will be well-positioned to thrive in an increasingly competitive and dynamic global marketplace.